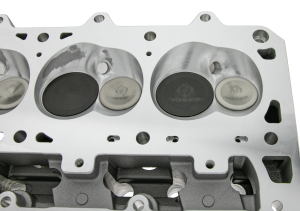

Frankenstein M311BM+ Boost-Monster+ 286cc LS3 CNC Ported 11 Degree Cylinder Head, 68cc Chambers, Assembled (30+psi)

Frankenstein redefined performance with The Monster—a game-changing cylinder head built with precision and power in mind. Featuring 5-axis CNC-ported intake and exhaust chambers, each head is hand-blended, deburred, and quality-checked to exacting standards. Built for 400ci+ stoker engines with higher compression applications (13:1+). Higher rpm (7500+). Higher boost levels (30psi+).

Looking to run high boost? check out the new "Boost Master" line of heads that features CHE mag-bronze valve guides and Inconel exhaust valves for the increased heat. While still fit all standard equipment such as valve covers, headers, LS3 Intakes, and OEM-type LS3 rocker arms. (Billet Rocker Stands Required to fit OE-Style LS3 Rocker Arms. Click on the product options button to add the stands.)

Sold as a single piece, 2 pieces required per engine.

*Notice, See Bottom of page for General Recommendations for Frankenstein Cylinder Heads

Description

Description |

Specification |

Min. Bore Dia. |

4.000” |

Intake Port Volume |

286cc |

Exhaust Port Volume |

112cc |

Combustion Chamber Volume |

68cc |

Guide Material |

CHE bronze guides |

Intake Valves |

FED Prime Grade Stainless Steel 2.165 |

Exhaust Valves |

FED Inconel 1.600 |

Valve Springs |

.700 Hydraulic Roller |

Retainers |

FED Titanium-64 – LS Dual Spring |

Valve Locks |

GM Valve Lock |

Valve Seals |

Viton High Heat Seal |

Billet Rocker Stands |

Not Included But Required for OE Style Rockers, PN: 913001 or see the product options |

Head Gasket Bore Size: |

4.125” Bore |

Head Bolts: |

6 Bolt |

Head Studs: |

7/16″ Stud Size (Drill to 1/2" Stud Size Available) |

Pushrods: |

8.100 – 8.250” Length x 3/8” Diam. |

Lifters: |

Standard |

Rockers: |

Standard LS3 w/FED Rocker Stand*Otherwise Shaft-Mount Rockers |

General Recommendations for Frankenstein Cylinder Heads:

Pushrods: Verify pushrod length and ensure at least .030” wall clearance. Do not enlarge pushrod holes further.

Surfacing: Milling affects flow and may require thicker intake gaskets and port alignment.

Boosted/Nitrous: Use Inconel exhaust valves and upgraded valve springs for reliability under high stress.

Marine: Use Inconel exhaust valves and consider hard-anodized coating for corrosion resistance.

Valve Guides: FED sets proper clearance, but boosted/nitrous/marine setups may need more—verify before use.

Valve Springs: Aggressive cams or power adders may need higher spring pressure. Check spring/cam compatibility before assembly.

Piston-to-Valve: Verify clearance (.080” intake, .100” exhaust, .030” radial). FED not responsible for damage due to improper clearance.

CNC Porting: Minor “as cast” areas are normal and don’t affect performance.

Installed Height: ±.015” variance is acceptable and harmless.

Rockers: Stock GM rockers aren’t suited for aggressive setups—use CHE trunnion kits.

O-Rings: Inspect and replace worn O-rings during service.

Head Studs: Confirm correct diameter and length for your setup.

Details

- FED-113040

- FED-113040

- Frankenstein Engine Dynamics

- New

Shipping Information

- Item Requires Shipping

- 35.0 lbs.

- W12.0000” x H12.0000” x L24.0000”

- Free Basic Shipping

- This item ships in its own box.

- FREE continental USA ground shipping on ALL Frankenstein Cylinder Heads

- TRE Performance Difference

- We're the ExpertsAsk us anything. We are the professionals!

- Largest SelectionIf you don't find the part, we'll get it for you!

- Have a question? Ask the Pros

- Email UsGet answers from the pros

- 877-514-9494Mon - Fri 8:00 AM - 4:00 PM PST