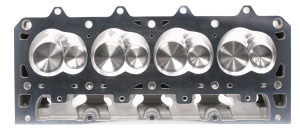

Frankenstein M113 Monster 273cc LS3 CNC Ported 11 Degree Cylinder Head, 68cc Chambers, Assembled

Your Selected Product

Frankenstein redefined performance with The Monster—a game-changing cylinder head built with precision and power in mind. Featuring 5-axis CNC-ported intake and exhaust chambers, each head is hand-blended, deburred, and quality-checked to exacting standards.

Looking to run high boost? check out the new "Boost Master" line of heads that features CHE mag-bronze valve guides and Inconel exhaust valves for the increased heat. While still fit all standard equipment such as valve covers, headers, LS3 Intakes, and OEM-type LS3 rocker arms. (Billet Rocker Stands Required to fit OE-Style LS3 Rocker Arms. Click on the product options button to add the stands.)

Sold as a single piece, 2 pieces required per engine.

*Notice, See Bottom of page for General Recommendations for Frankenstein Cylinder Heads

Description

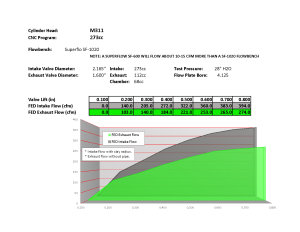

273cc LS3 Monster-Series Cylinder Head Flow Chart |

|||||||

|

|

.200 |

.300 |

.400 |

.500 |

.600 |

.700 |

.800 |

Int |

140 |

205 |

272 |

322 |

360 |

383 |

394 |

Exh |

103 |

140 |

184 |

221 |

253 |

265 |

274 |

Description |

Specification |

Min. Bore Dia. |

4.000” |

Intake Port Volume |

273cc |

Exhaust Port Volume |

112cc |

Combustion Chamber Volume |

68cc |

Intake Valves |

FED Prime Grade Stainless Steel 2.165 |

Exhaust Valves |

FED Prime Grade Stainless Steel 1.600 |

Valve Springs |

Dual .700 Hydraulic Roller |

Retainers |

FED Titanium-64 – LS Dual Spring |

Valve Locks |

GM Valve Lock |

Valve Seals |

Viton High Heat Seal |

Billet Rocker Stands |

Not Included But Required for OE Style Rockers, PN: 913001 or see the product options |

Head Gasket Bore Size |

4.125” Bore |

Gasket Seat – .708” Reach PLEASE VERIFY |

|

Tapered Seat – .708” Reach PLEASE VERIFY |

|

Pushrods: |

8.100 – 8.250” Length x 3/8” Diam. |

Lifters: |

Standard |

Rockers: |

Standard LS3 w/FED Rocker Stand

|

General Recommendations for Frankenstein Cylinder Heads:

Pushrods – Please make sure to properly check pushrod length and wall clearance. We recommend a clearance of at least .030” between the pushrod and the wall. Please do not clearance the pushrod holes any further. We have a minimum port thickness required to pass QC and that is set at our facility. Every lifter brand and style use a different pushrod length, so make sure to properly check the length needed for your application.

Surfacing – Flat or angle milling will affect flow numbers and may require a thicker intake gasket. The intake manifold will also need to be corrected to match the intake ports for optimal performance.

Boosted/Nitrous Applications – With any power adder applications comes increased stress and longevity issues for the valvetrain. We highly suggest the use of Inconel exhaust valves in any power adder combos. We also suggest our upgraded valve spring kits to help properly control the valve train in these stressful conditions.

All MARINE Applications – We strongly recommend Inconel exhaust valves & also offer a hard-anodized coating to slow the effects of corrosion. Please see note on guide clearance below.

Valve Guide Clearance – Your FED Heads come with proper guide clearance for most applications. Boosted/Nitrous or marine applications might require additional clearance and it is the customer’s responsibility to verify proper clearance in these applications.

Valve Springs – Forced induction, nitrous oxide and cams with aggressive ramp rates may require additional spring pressure. We offer upgraded valve springs for these types of applications. FED also recommends the use of billet 8620 cam cores and high-quality lifters. VALVE SPRINGS MAY NOT BE COMPATIBLE WITH YOUR CAMSHAFT COMBINATION. PLEASE CHECK BEFORE ENGINE ASSEMBLY. IMPROPER SPRING AND CAMSHAFT COMBO CAN CAUSE SEVERE DAMAGE.

Piston to Valve – FED assumes no responsibility for damage if the end user builds an engine without properly verifying he or she has enough piston to valve clearance (depth and radial clearance both checked). We recommend a minimum depth of .080″ on the intake valve and .100″ on the exhaust with a radial clearance of .030″ minimum around the perimeter of each valve. Just checking depth is not enough, the position of the valve pocket must also be addressed. It is the customers responsibility to verify proper piston to valve clearance.

CNC Porting – Occasionally a 100% CNC ported head might have a very small area left “as cast”, this in no way affects performance.

Valve Spring Installed Heights – FED valve spring installed height spec is +/- .015” which is the smallest shim available for adjustment. This small of a difference will have no issues and should be of no concern.

Stock GM Rocker Arms – GM Rocker Arms are not designed/engineered to endure aggressive aftermarket cams or higher spring pressures/rates. At a minimum FED recommends using CHE Bushing Trunnion Kits. Without the proper parts you will experience accelerated guide wear over an extended period.

O-Rings – O-rings will wear out over time. Removal of components, such as headers for example, may cause O-rings to wear faster. We highly recommend a thorough inspection of any O-rings during removal and prior to installation. Worn or damaged O-rings should be replaced.

Head Stud Sizes- Make sure to get the proper head stud diameter and length for your head and block combo.

- TRE Performance Difference

- We're the ExpertsAsk us anything. We are the professionals!

- Largest SelectionIf you don't find the part, we'll get it for you!

- Have a question? Ask the Pros

- Email UsGet answers from the pros

- 877-514-9494Mon - Fri 8:00 AM - 4:00 PM PST