LS 1000cc DeatschWerks Fuel Injectors Kit - Will Fit Any LS Rail, Manifold & Engine

The DeatschWerks all-inclusive injector kit offers a comprehensive solution to all your injector need. With all the necessary adapters, spacers, clips, connectors & o-rings included, this kit makes it easy to install your injectors with minimal hassle. This kit is designed to be a all in one kit!

Note: This kit is a injector set of 8 for ANY LS Manifold / Fuel Rail / Engine Combination!

Description

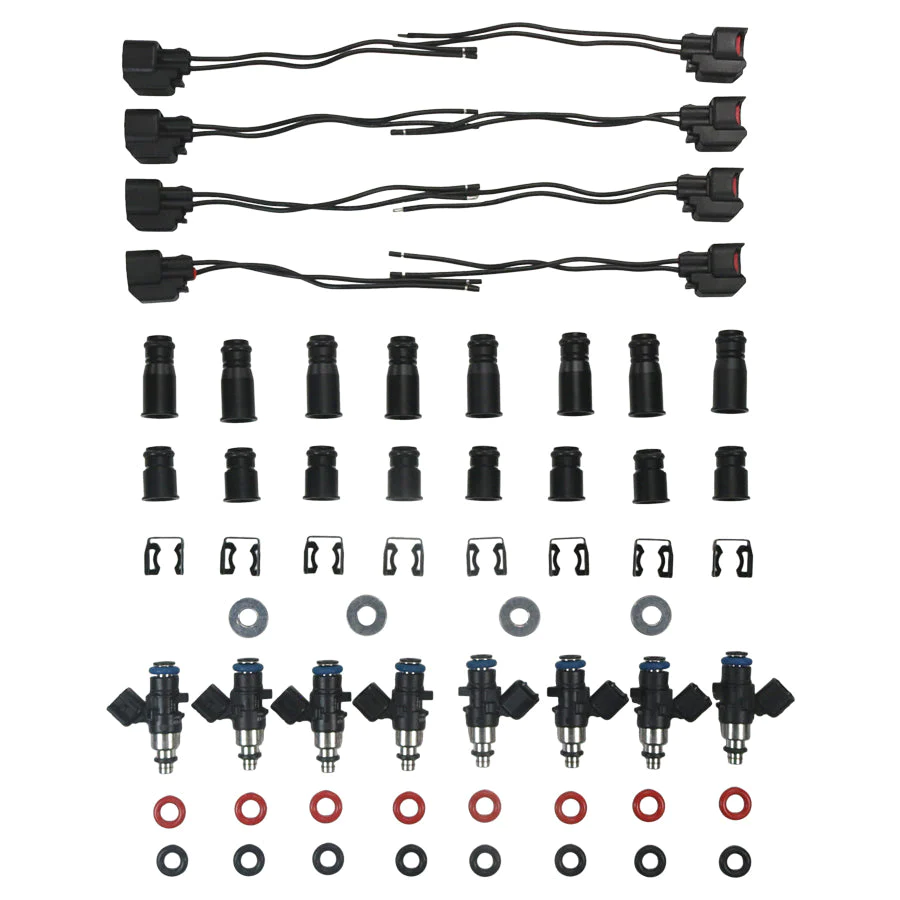

What's In The Box?:

8 - 1000cc Short DeatschWerks Fuel Injectors

8 - EV6 Pigtails

8 - Midlength Injector Adapters

8 - Tall Injector Adapters

8 - Adapter Clips

4 - Non-Flex Fuel OE Truck Fuel Rail Spacers

8 - 15.5MM Lower O-Ring - Orange

8 - 14.6MM Lower O-Ring - Black

Engine Fitments:

LS1, LS2, LS3, LS6, LS7, LS9, LSA, L20, L33, L59, L92, L94, L9H, LH6, LH8, LM7, LZ1, LS4, LMG, LQ4, LQ9, LR4, LY2, LY5, LY6, L76, L99

Specifications:

Flow Rate in CC per minute: 635 CC/min @ 29.0 PSI

Flow Rate in LB per hour: 60.5 LBS/HR @ 29.0 PSI

Flow Rate in CC per minute: 784 CC/min @ 43.5 PSI

Flow Rate in LB per hour: 74.6 LBS/HR @ 43.5 PSI

Flow Rate in CC per minute: 903 CC/min @ 58.7 PSI

Flow Rate in LB per hour: 86.0 LBS/HR @ 58.7 PSI

Flow Rate in CC per minute: 1022 CC/min @ 72.5 PSI

Flow Rate in LB per hour: 97.4 LBS/HR @ 72.5 PSI

Resistance: 12.5 ohms (High Impedance, High Resistance)

Max Nominal Pressure: 72.5 PSI

Injector Body Design: Metal and composite plastic

Proper Data is a Must

The right tool, used incorrectly, yields substandard results at best. Fuel injectors follow this same universal law. Proper data is required for proper tuning. All DW injectors are fully characterized in-house via SAE J1832 standards. Injector data is available in General Characterization Summaries and Application Specific formats. Using the data is easy. Often it is cut and paste from the DW excel sheet to the tuning software.

Development of accurate injector data is a complex process, but there are no shortcuts to a proper calibration. DW has developed specially designed and calibrated flow benches utilizing digital flow meters, which are required to measure the precise fuel mass needed for proper characterizations. The data acquisition process consists of collecting over 450 data points per injector part number. These data points cover pulse widths, pressures, and voltages that the injectors will experience once installed in your engine. The collected data is statically analyzed, scrubbed and formatted into a General Characterization Summary. This Summary can then be formatted into application-specific formats for different makes, models, and tuning platforms. The application specific data is then in-car optimized by one of our tuning partners.

Dynamic Flow Matching

Quality injectors mated to proper calibration data will still perform poorly as a system if the injector set is not properly flow matched. The DW dynamic flow matching process ensures each set works together as a system to fuel your engine properly. Fuel injectors do not operate in a static state so why test them in a static state? In the engine, fuel injectors are a very dynamic component, constantly changing frequencies and pulse widths to precisely deliver the fuel needed. The DW multi-point dynamic flow testing process mimics these conditions by testing at multiple pulse widths within each of the ranges below…

- Low Range (1-2 milliseconds) – Low pulse widths are used during idle, light throttle cruising, and deceleration. However, expensive electronic flow meters are required for accurate testing in this range so few companies actually balance their injectors this low. Low pulse width balancing is crucial for a smooth idle on large injectors.

- Transitional Range (2-4 milliseconds) – The transitional range covers the pulse widths that typically make up the non-linear range of injectors. Although most DW injectors are linear well into the low pw range, transitional balance is important because many high flow injectors spend a majority of time in this range.

- Linear Range (4-10+ milliseconds) – The linear range pulse widths are used during medium and high load conditions. Proper balancing in this range allows for advanced timing and increased boost pressure to yield higher and safer peak horsepower.

- Static Flow - Many companies that balance their injectors only test at static flow. In the engine, injectors do not operate at a static state. However, the static rate is still considered the “call-size” of the injector.

Details

- 16U-LS-1000-8

- 16U-LS-1000-8

- DeatschWerks

- New

Shipping Information

- Item Requires Shipping

- 4.0 lbs.

- W5.0000” x H5.0000” x L5.0000”

- Free Basic Shipping

- FREE Fast Priority Mail shipping to the USA and it's territories on ALL Fuel Injectors.

- TRE Performance Difference

- We're the ExpertsAsk us anything. We are the professionals!

- Largest SelectionIf you don't find the part, we'll get it for you!

- Have a question? Ask the Pros

- Email UsGet answers from the pros

- 877-514-9494Mon - Fri 8:00 AM - 4:00 PM PST