Injector Dynamics ID2600-XDS Fuel Injectors 2004-2006 Dodge Ram SRT10

Nominal Flow Rate – 2600cc/min @ 43.5 psi (3 Bar)

Maximum Differential Fuel Pressure – 130.5 psi (9 Bar) - Requires Minimum 11 volt

Fuel Compatibility – Compatible with Methanol/Ethanol/All Known Hydrocarbon Fuels. NOT Compatible with Ethers (MTBE, ETBE, TAME) or Nitro Methane.

Electrical Connector – EV6 / USCAR

Description

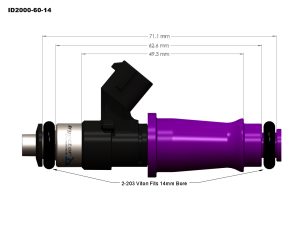

Included: 10 Injector Dynamics ID2000 fuel injectors. The photo is an example of a similar set.

Injector Dynamics is proud to release the latest X-Series injector, the ID2600-XDS. Like the 1050x, 1300x², and 1700x, The ID2600-XDS is an exclusive development from the partnership of Injector Dynamics and Bosch Motorsport. The ID2600-XDS was developed specifically for use with liquid fuels, featuring corrosion resistant internals, and long term compatibility with ethanol and methanol.

These injectors have the highest flow rate of any injector offered by Bosch, and flows 50% more than the ID1700x. The ID2600-XDS benefits from Dual Slope Matching, a method of matching the flow rate in both the linear, and nonlinear operating range, providing better cylinder to cylinder consistency at low pulse widths.

These Injector Dynamics fuel injectors will fit many applications, including, but not limited to:

2004-2006 Dodge Ram SRT10 8.0L.

Specifications

Typical Flow Rate in CC per minute: 2600cc/min @ 3.0 Bar (43.5 psi) Using Iso Octane at 52 Degrees C (125 Degrees F)

Maximum Differential Fuel Pressure – 9.0 Bar (130.5 psi) Requires Minimum 11volt

Fuel Compatibility – Compatible with Methanol / Ethanol / All Known Hydrocarbon Fuels. NOT Compatible with Ethers (MTBE, ETBE, TAME) or Nitro Methane.

Electrical connector type: EV6 / USCAR

Injector Body Design: Metal and composite plastic

O-Rings Included: Yes, on the injectors

Length of injector from o-ring to o-ring: 60mm

Diameter of top o-ring / fuel rail bore: 14mm

Diameter or style lower o-ring or cushion: 14mm - late model GM lower o-ring

Injector Dynamics Dual Slope Matching:

Dual Slope Matching is a method of matching injectors that provides the best possible cylinder to cylinder fueling across the entire operating range. Traditionally, injectors were matched based on static flow rate alone, which resulted in large deviations at low pulse widths. Injector Dynamics introduced Slope Intercept Matching over a decade ago, which provided even cylinder to cylinder fueling across the linear operating range of the injector. With the progression of turbo technology, and increased use of alcohol fuels, greater demands are placed on fuel injectors, and they are often required to deliver fuel well outside of their linear operating range.

The concept of Dual Slope Matching extends the injector matching into the lower non linear operating range. Dual Slope Matching was conceived by Aaron Looft of Injector Dynamics, who was inspired by the dual slope injector characterization model used by Ford.

By approximating the response in the non linear range, and matching sets accordingly, the best possible cylinder to cylinder fueling is realized across the entire operating range. Using the ID2600-XDS as an example, the traditional Slope Intercept method of matching results in an average deviation of +/-5.1% in the non linear range, while the new method of Dual Slope Matching has reduced this to +/-1.4%! In a perfect world, this deviation would not exist at all, but for those of us who live (And tune!) in the real world, Dual Slope Matching represents a large step forward, and we are proud to offer it to the market.

Injector Dynamics Data:

Are you tired of pouring over logs, making corresponding changes to your tune, only to find that what worked one day is off by the next? Have you wasted hours sifting through a myriad of injector related forum posts, only to find that there is no simple solution? Such is the nature of tuning with inaccurate injector data. Accurate injector characterizations are the basis of all fueling calculations, so it’s no wonder that if you’re tuning without them, you will spend a lot of valuable time making the best of a bad situation. It will keep you busy searching for endless combinations of mostly incorrect answers, and it will rob you of the most basic functions provided by the guys who spent millions of R&D dollars designing the engine management system for your car. Whether you are a professional tuner, or an end user, you can spend countless hours getting it “mostly correct” or you can copy and paste accurate characterization tables and get on with the job of maximizing performance and drivability. Injector Dynamics is the only motorsport injector supplier capable of generating these OEM quality injector characterizations, and our engineering services are available to generate data for new platforms and applications at no cost to our customers.

Please contact us directly for more details about these new ID2600-XDS injectors including the design process and more specifications - 1-760-586-5617

Slope and Offset vs. Pressure data available upon request.

Details

- ID2600.60.14.14.10

- ID2600.60.14.14.10

- Injector Dynamics

- New

Shipping Information

- Item Requires Shipping

- 2.0 lbs.

- W5.0000” x H5.0000” x L5.0000”

- Free Basic Shipping

- FREE UPS Next Day Air or USPS Express Mail available! Just leave a note with your preference.

- TRE Performance Difference

- We're the ExpertsAsk us anything. We are the professionals!

- Largest SelectionIf you don't find the part, we'll get it for you!

- Have a question? Ask the Pros

- Email UsGet answers from the pros

- 877-514-9494Mon - Fri 8:00 AM - 4:00 PM PST